Stud welding machines have revolutionized the welding industry, offering a reliable and efficient method for creating strong and durable welds. These machines, widely used across various sectors, bring forth a myriad of benefits and applications that have transformed the way we connect and build structures. In this post, we will delve into the capabilities and advantages of stud welding machines, showcasing their immense value in today’s industrial landscape.

- Versatility in Applications: Stud welding machines showcase their versatility by catering to a wide range of applications. From construction and manufacturing to automotive and shipbuilding industries, these machines deliver exceptional performance in creating secure connections. Whether it’s welding studs to steel structures, ship components, automotive frames, or machinery, stud welding machines offer the flexibility needed for diverse projects.

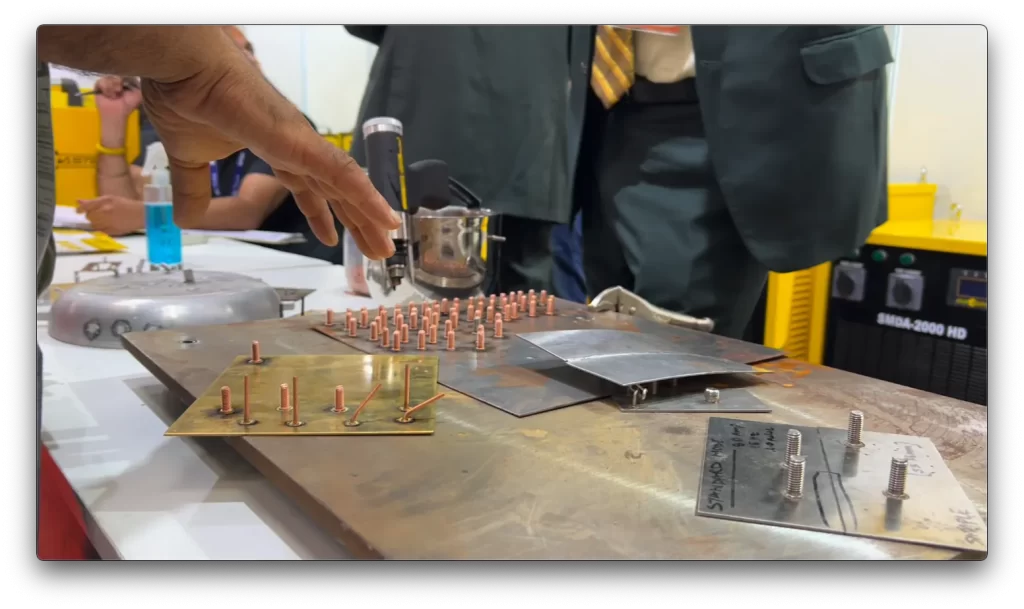

- Rapid and Efficient Welding: One of the key advantages of stud welding machines is their ability to deliver rapid and efficient welding. By generating intense heat and utilizing advanced techniques such as drawn arc or capacitor discharge, these machines enable quick melting and fusion of studs with base materials. This not only saves time but also boosts overall productivity, making stud welding machines a preferred choice for time-sensitive projects.

- Strong and Durable Connections: Stud welding machines excel in producing strong and durable welds that withstand heavy loads and extreme conditions. The solid fusion between the stud and base material creates a robust connection with high shear strength, ensuring structural integrity and longevity. This reliability makes stud welding machines an essential tool in critical applications where safety and performance are paramount.

- Ease of Use and Consistency: Stud welding machines are designed for user-friendliness, providing operators with intuitive controls and adjustable parameters. This simplifies the welding process and allows for precise customization based on specific project requirements. Additionally, these machines deliver consistent weld quality, ensuring uniformity and reliability across all welds.

- Cost-Effective and Efficient: Stud welding machines offer cost-effective solutions in terms of material usage and labor efficiency. The ability to weld studs of various sizes and materials minimizes the need for additional connectors, reducing material costs. Furthermore, their high welding speeds and efficient operation contribute to increased productivity and reduced labor expenses.

Stud welding machines have revolutionized the welding industry by providing versatile, efficient, and reliable solutions for creating robust connections. Their applications span across construction, manufacturing, automotive, and shipbuilding sectors, delivering rapid and durable welds. By combining ease of use, cost-effectiveness, and consistent weld quality, stud welding machines have become indispensable tools for achieving exceptional welding results. Embrace the power of stud welding machines and unlock a new level of welding excellence in your projects.

See the STUDMASTER® STUD WELDING PRODUCTS